Ever since World War II, Japan had been devising ways to bring about an economic boom targeted at its recovery. Japan had been following Kaizen business model for this purpose. In 1986, the United States came up with Six Sigma with its first implementation in Motorola Inc. In the 1990’s this was adopted by General Electric also and in the early years of the 21st Century, Six Sigma and Lean collaborated to bring about Lean Six Sigma.

Lean is a managerial concept that aims at reducing the seven kinds of waste while Six Sigma focuses on reducing processes variations of all sorts thereby helping to link the processes together tightly.

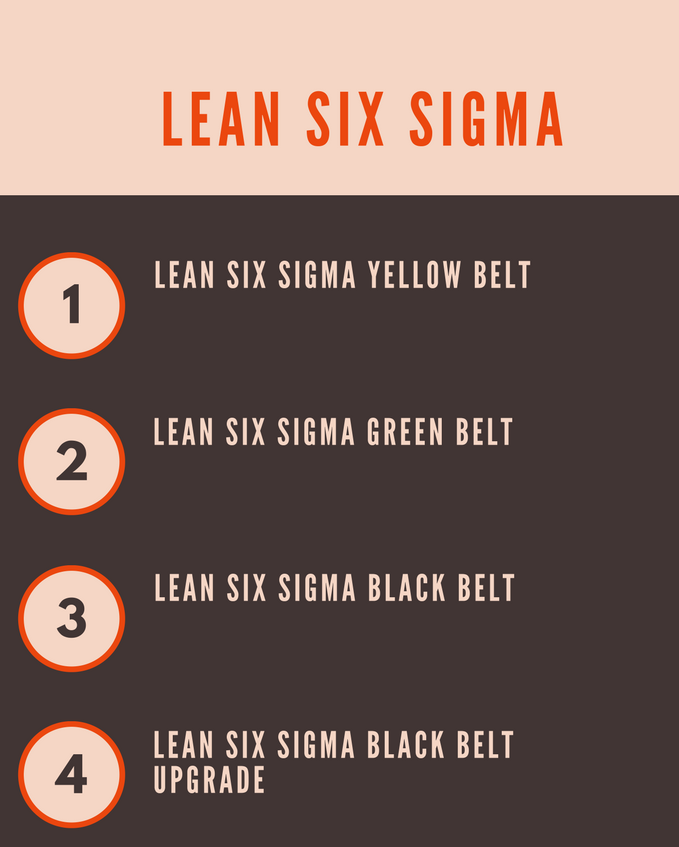

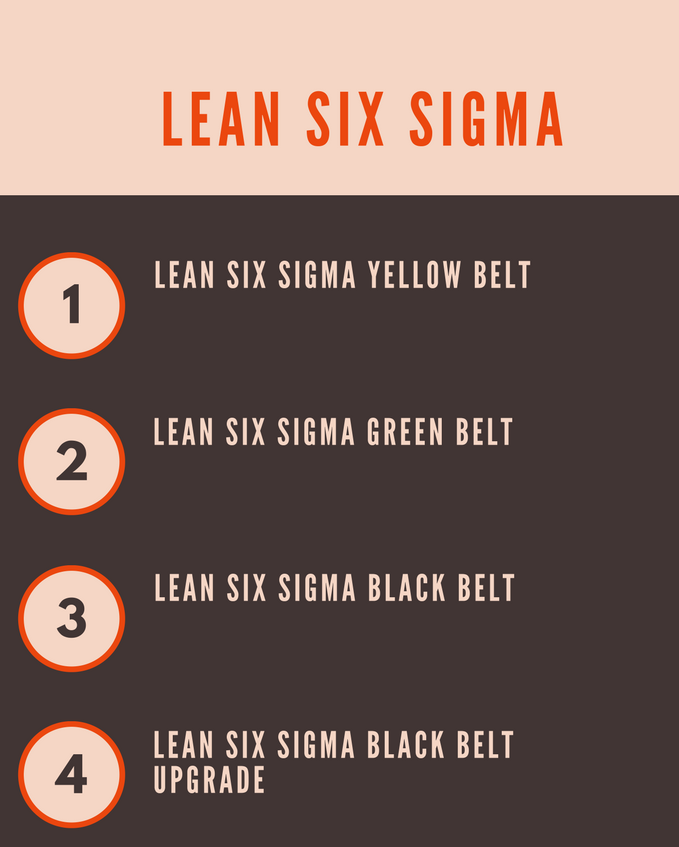

Lean Six Sigma provides various levels of certifications each providing the delegate with a higher understanding of Lean Six Sigma. These certifications are shown in the figure.

Those delegates who wish to sit for the exam they have taken some training from an authorised/accredited institute, or trainer, though this is not a prerequisite.Again, delegates wishing to sit for the exam must also have a real-world Lean Six Sigma project experience(this is also only recommended and not required).

On completion of the course and the exam, the delegates are certified by the International Association for Six Sigma Certification™ as Belk Belt Certified Professionals. The only third party Certification Association within the Lean Six Sigma Industry is the IASSC.

Exams

The Lean Six Sigma Black Belt Exam takes place during the second Friday afternoon at the end of the course. The Lean Six Sigma Black Belt Exam contains 150 questions. It a closed book proctored exam that lasts for 4-hours.

ENQUIRE

ENQUIRE

REQUEST CALLBACK

REQUEST CALLBACK

GET A FREE QUOTE

GET A FREE QUOTE

Introduction

Introduction Course Details

Course Details Course Content

Course Content

London

London